Product Description

Long Stroke Multistage Telescopic Single Acting Lift Hydraulic Cylinder for Mining Dump Truck Spare Parts Made in China

Product Specifications:

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 5stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,Customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,Customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

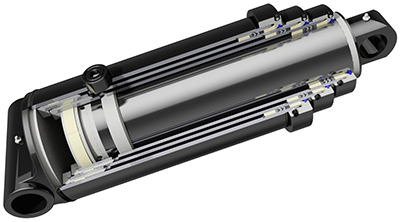

Product Display:

Mounting Method:

Appliactions:Mining Machinery,Mining Dump Truck

Other Related Products

Our Factory:

Quality Assurance:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

Our Main Customers

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 2100/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be used in construction equipment like cranes?

Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation:

Role in crane operation:

Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances.

Extension and retraction mechanism:

The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system.

Hydraulic control system:

The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane.

Load handling capabilities:

Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities.

Variety of crane types:

Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations.

Advantages of telescopic cylinders in cranes:

Telescopic cylinders offer several advantages in crane applications. These include:

- Compactness: Telescopic cylinders enable the boom to be retracted to a compact size, making it easier to transport and maneuver the crane in confined spaces.

- Reach and height capabilities: The telescopic design allows the crane to achieve extended reach and height, enabling it to access elevated work areas or reach over obstacles.

- Efficiency: The controlled extension and retraction of telescopic cylinders contribute to efficient operation, allowing the crane to adjust its boom length quickly and precisely.

- Stability: Telescopic cylinders provide stability to the crane by supporting the boom and load, ensuring safe lifting and lowering of heavy objects.

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks.

It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

Can telescopic cylinders be used in mining equipment for material transport?

Yes, telescopic cylinders are commonly used in mining equipment for material transport tasks. Here’s a detailed explanation:

Material loading and unloading:

Telescopic cylinders play a crucial role in loading and unloading materials in mining operations. They are utilized in equipment such as wheel loaders, excavators, and dump trucks. Telescopic cylinders enable the lifting and lowering of buckets, forks, or other material handling attachments, facilitating efficient material transport.

Extended reach:

In mining equipment, telescopic cylinders offer extended reach capabilities. This allows operators to access materials located at various distances, heights, or depths. The telescopic design of the cylinders enables them to extend and retract, providing the necessary reach for loading and unloading materials in mining applications.

Precise control:

Telescopic cylinders provide precise control over material transport movements. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, allowing operators to achieve accurate positioning and controlled movements during loading, unloading, and material placement. This precise control is essential for optimizing productivity and safety in mining operations.

Load handling capacity:

Telescopic cylinders are designed to handle heavy loads encountered in mining environments. They provide the necessary lifting force to transport large volumes of materials, such as ore, rocks, or overburden. The cylinders are engineered to withstand the demanding conditions of mining operations and ensure safe and efficient load handling.

Adaptability to terrain:

Mining equipment operates in diverse terrains, including uneven surfaces or steep inclines. Telescopic cylinders offer adaptability to varying terrain conditions. The extended reach and controlled movements provided by the cylinders allow operators to navigate challenging terrains and transport materials efficiently in mining sites.

Support for attachments:

Telescopic cylinders often support a range of attachments or tools that enhance material transport capabilities in mining equipment. For example, in wheel loaders, telescopic cylinders are used to extend the lifting arms, while different attachments such as buckets or forks facilitate the handling of various materials.

Advantages of telescopic cylinders in mining equipment:

Telescopic cylinders offer several advantages in material transport applications within mining:

- Extended reach: Telescopic cylinders enable operators to access materials located at varying distances or depths.

- Precise control: The hydraulic control system allows for accurate positioning and controlled movements, enhancing productivity and safety.

- Heavy-load handling: Telescopic cylinders provide the necessary lifting force to transport large volumes of materials encountered in mining operations.

- Adaptability to terrain: The extended reach and controlled movements of telescopic cylinders facilitate material transport in diverse mining terrains.

- Support for attachments: Telescopic cylinders can be used in conjunction with attachments or tools that enhance material handling capabilities in mining equipment.

Overall, telescopic cylinders are widely used in mining equipment for material transport tasks, offering extended reach, precise control, load handling capacity, adaptability to terrain, and support for attachments. They contribute to the efficiency, productivity, and safety of material transport operations in mining.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in mining equipment.

Can you explain the purpose and role of telescopic cylinders in machinery?

Telescopic cylinders play a crucial role in various machinery and equipment applications. Here’s a detailed explanation:

Purpose of telescopic cylinders:

Telescopic cylinders are primarily used when an extended stroke length is required while maintaining a compact retracted length. They enable machinery and equipment to achieve extended reach, height adjustment, or lifting capabilities without increasing the overall size or footprint of the cylinder. The purpose of telescopic cylinders is to provide efficient and reliable linear motion in applications that demand long stroke lengths.

Role of telescopic cylinders in machinery:

- Material Handling: Telescopic cylinders are extensively used in material handling machinery, such as cranes, forklifts, and loaders. They enable the extension and retraction of booms, arms, or lifting mechanisms, allowing operators to reach higher or farther to handle and transport materials with ease.

- Dump Trucks and Trailers: Telescopic cylinders are commonly employed in dump trucks and trailers for the tilting and unloading of cargo or bulk materials. The extendable stroke of the cylinder raises the bed or container to dump the contents, enabling efficient unloading and reducing manual labor.

- Aerial Platforms: Telescopic cylinders are essential components in aerial work platforms, such as cherry pickers or scissor lifts. They facilitate the vertical movement and height adjustment of the platform, allowing operators to access elevated work areas safely.

- Construction Equipment: Telescopic cylinders are used in various construction equipment, including excavators, backhoes, and telescopic handlers. They provide the necessary extension and retraction for the boom, arm, or bucket, enabling digging, lifting, and reaching capabilities in construction and earthmoving applications.

- Mobile Equipment: Telescopic cylinders are utilized in mobile equipment, such as telescopic cranes and mobile cranes. They enable the extension and retraction of the boom sections, allowing for increased reach and lifting capacities in lifting and construction operations.

- Specialized Machinery: Telescopic cylinders find application in specialized machinery, such as fire truck aerial ladders, telescopic masts, or telescopic booms in industrial and military equipment. They provide the required extension and retraction for specific tasks, such as firefighting, surveillance, or equipment deployment.

The role of telescopic cylinders in machinery is to provide precise and controlled linear motion, enabling the equipment to perform specific tasks with extended reach, height adjustment, or lifting capabilities. They contribute to the efficiency, versatility, and productivity of machinery in various industries.

It’s important to ensure proper selection, installation, and maintenance of telescopic cylinders based on the specific machinery requirements and manufacturer’s guidelines to ensure safe and reliable operation.

editor by Dream 2024-05-09

Leave a Reply