Product Description

Product description:

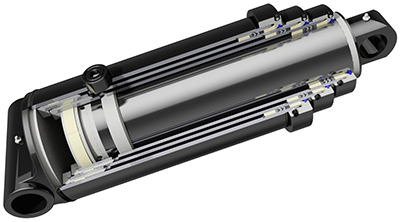

Junfu is famous brand in front-end cylinders, offering an extensive catalogue from 5 to 100 tons with bespoke solutions. Designed for rear-end tippers and tippers trailers, CHINAMFG brand front-end telescopic cylinders are known for their durability, reliability in all conditions and value for money. We believe in delivering a solution that can rapidly and successfully meet your requirements in demanding industries such as transportation, construction and mining. With high payload and longer service intervals for increased operating time, CHINAMFG brand front-end cylinders are also environmentally friendly solutions with lower oil & fuel consumption.

FC telescopic front-end cylinders are primarily designed for straight headboard dump trucks with a capacity range of over 100 tons tipping weight. Our trunnion type FC cylinder is lightweight, strong, maintenance free and offers the most added stability to the tipper. The CHINAMFG brand FC tipping cylinders have earned reputation for their reliability and value for money over many years.

Designed for for Dump Truck applications, FC series cylinder with 3-6 stages is capable of lifting more weight which in return allows trucks to be equipped with smaller cylinders reducing space and saving weight. This CHINAMFG series cylinder is mostly used in combination with a Straight Headboard Type and Trunnion Type Body Connection.

Workshop with advanced equipment:

Certificates: ISO9001, IATF 16949:2016, CE,etc.

FAQ:

Q1: How about your cylinders compared with HYVA cylinder ?

Our cylinders can replace HYVA cylinder well, with same technical details and mounting sizes

Q2: What’s your cylinder’s advantages ?

The cylinders are manufactured by advanced equipments and made under strictly quality control processing.

The steel is quenched and tempered and all raw materials are good quality from world famous companies.

Competitive price!

Q3: When your company be established ?

Our company be established in 2002, professional manufacturer of hydraulic cylinders more than 20 years.

We had passed IATF 16949:2016 Quality control system, ISO9001, CE,etc.

Q4: How about the delivery time ?

15 days approximately.

Q5: How about the cylinder’s quality gurantee ?

One year.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001, IATF 16949:2016, SGS |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

Can telescopic hydraulic cylinders be used in construction equipment like cranes?

Yes, telescopic hydraulic cylinders can be used in construction equipment like cranes. Here’s a detailed explanation:

Telescopic hydraulic cylinders are commonly employed in various types of cranes due to their unique features and capabilities.

Boom Extension and Retraction:

One of the key functions of a crane is to extend and retract its boom to reach different heights and distances. Telescopic hydraulic cylinders are well-suited for this purpose as they offer long stroke lengths, allowing the crane to have extended reach capabilities. The ability to extend and retract multiple stages of the cylinder enables the boom to be adjusted to the desired length, providing versatility in various lifting and reaching tasks.

Compact Design:

In crane applications, space can be a limiting factor, especially when operating in confined construction sites or urban areas. Telescopic hydraulic cylinders have a compact design compared to other types of cylinders, making them ideal for cranes where space optimization is crucial. The ability to retract to a shorter length when not in use allows for easier installation and maneuverability in tight spaces.

High Load Capacity:

Crane operations often involve lifting and moving heavy loads. Telescopic hydraulic cylinders are designed to handle high load capacities, making them suitable for the demanding lifting tasks performed by cranes. The multiple stages of the cylinder provide additional strength and stability, allowing cranes to lift substantial weights with ease.

Precise Control:

Crane operators require precise control over the extension and retraction of the boom for safe and accurate load handling. Telescopic hydraulic cylinders offer smooth and controlled operation, thanks to the hydraulic system’s ability to regulate pressure and flow. This precise control allows the crane operator to make gradual and accurate adjustments to the boom’s length, enhancing the overall safety and efficiency of the lifting operation.

Stability and Safety:

Telescopic hydraulic cylinders contribute to the stability and safety of cranes. The multiple stages of the cylinder can be locked in position, minimizing unwanted movement or swaying during load handling. This ensures that the crane remains stable and secure while lifting or moving heavy loads, reducing the risk of accidents or damage to the surrounding environment.

Overall, telescopic hydraulic cylinders are a suitable choice for construction equipment like cranes. Their capabilities in boom extension and retraction, compact design, high load capacity, precise control, stability, and safety make them well-suited for the demanding lifting tasks performed by cranes in construction applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, operation, and maintenance of telescopic hydraulic cylinders in crane applications.

How do telescopic hydraulic cylinders handle variations in cylinder size and capacity?

Telescopic hydraulic cylinders are designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

Telescopic hydraulic cylinders offer the ability to adjust the length and capacity of the cylinder to meet specific requirements. This versatility allows them to accommodate variations in cylinder size and capacity. Here are some key factors that contribute to their ability to handle such variations:

Multiple Stages:

Telescopic hydraulic cylinders consist of multiple stages, typically three to five, nested inside one another. Each stage can be extended and retracted independently, providing incremental changes in the overall length of the cylinder. By adjusting the extension of each stage, the cylinder size can be modified to fit different applications. This flexibility allows telescopic cylinders to handle variations in cylinder size effectively.

Modular Design:

Telescopic hydraulic cylinders have a modular design, which means that the individual stages can be added or removed as needed. This modular construction allows for easy customization of the cylinder size and capacity. Additional stages can be added to increase the overall length and capacity, while stages can be removed to decrease them. This modular design ensures adaptability to different cylinder size requirements.

Interlocking Mechanism:

The stages of telescopic hydraulic cylinders are designed with an interlocking mechanism that provides stability and strength when fully extended. This mechanism ensures that the stages remain securely locked in place during operation, preventing unwanted movement or deflection. The interlocking design contributes to the ability of telescopic cylinders to handle variations in cylinder size without compromising performance or safety.

Load Capacity:

Telescopic hydraulic cylinders are engineered to handle varying load capacities. Each stage of the cylinder is designed to support a specific load, and the load capacity increases with the addition of more stages. The stages are carefully sized and reinforced to ensure structural integrity and reliable performance under different load conditions. This enables telescopic cylinders to handle variations in cylinder capacity effectively.

Application-Specific Customization:

Telescopic hydraulic cylinders can be customized to meet specific application requirements. Manufacturers offer a range of options for cylinder size, capacity, and other specifications, allowing customers to choose the most suitable configuration for their needs. This customization ensures that telescopic cylinders can handle variations in cylinder size and capacity across different industries and applications.

Overall, telescopic hydraulic cylinders handle variations in cylinder size and capacity through their multiple stages, modular design, interlocking mechanism, load capacity, and application-specific customization. These features provide flexibility, adaptability, and reliable performance, making telescopic cylinders a versatile choice for a wide range of hydraulic applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, operation, and maintenance of telescopic hydraulic cylinders to handle variations in cylinder size and capacity.

What are the key components and design features of a telescopic hydraulic cylinder?

A telescopic hydraulic cylinder consists of several key components and incorporates specific design features to enable its functionality. Here’s a detailed explanation:

Key Components:

1. Cylinder Barrels: The cylinder barrels are the outermost components of a telescopic hydraulic cylinder. They provide the external structure and house the internal stages.

2. Stages: The stages are cylindrical sections that telescope or extend and retract within each other. They vary in diameter, with each stage fitting inside the previous one. The stages are responsible for providing the linear motion of the cylinder.

3. Pistons: Each stage of the telescopic cylinder has a corresponding piston that moves within it. The pistons are connected to the stages and transmit the hydraulic pressure to extend or retract the cylinder.

4. Hydraulic Seals: Hydraulic seals are used between the stages to prevent fluid leakage and maintain pressure within the cylinder. These seals ensure efficient operation and prevent contamination of the hydraulic fluid.

5. Rods: The rods are located at the end of the innermost stage and provide the point of attachment for external loads or equipment.

Design Features:

1. Telescoping Design: The telescopic design of the cylinder allows for multiple stages to extend and retract within each other, providing a greater range of linear motion compared to standard hydraulic cylinders.

2. Varying Diameter: Each stage of a telescopic cylinder has a different diameter, allowing them to fit inside one another. This design feature enables the nested construction and length adjustment capabilities of the cylinder.

3. Locking Mechanisms: Telescopic cylinders may incorporate locking mechanisms to secure the extended stages in position. These mechanisms ensure stability during operation and prevent unintentional retraction of the stages.

4. Hydraulic Connections: The telescopic cylinder is connected to a hydraulic system through hydraulic fittings. These connections allow the hydraulic fluid to enter and exit the cylinder, enabling the extension and retraction of the stages.

5. Mounting Options: Telescopic cylinders are designed to be mounted in various orientations and configurations depending on the specific application. Mounting options may include flange mounts, clevis mounts, or other types of mounting brackets.

6. Protective Coatings: Telescopic cylinders may have protective coatings or finishes to enhance their durability and resistance to corrosion, wear, and environmental factors.

These key components and design features work together to enable the telescopic hydraulic cylinder to achieve extended reach and adjustable length in various applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the construction, operation, and maintenance of telescopic hydraulic cylinders.

editor by Dream 2024-05-09

Leave a Reply